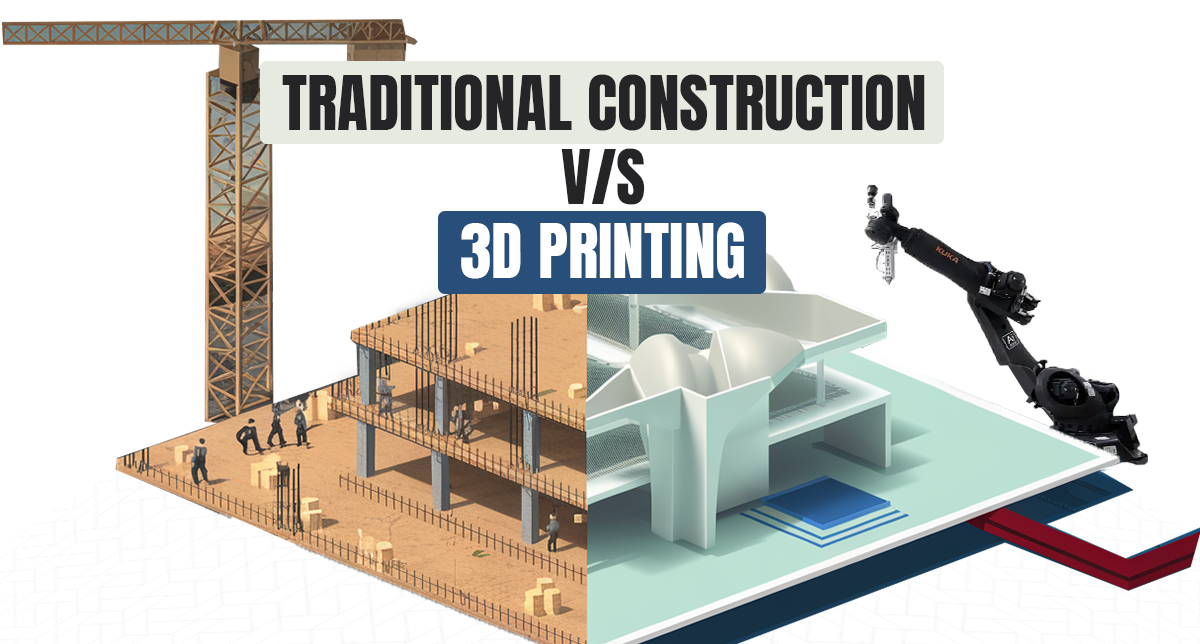

Building and construction have always been there since recorded human history. In today’s time with growing complexities, it’s a challenging task. Constructing a structure needs for a thorough strategy that is all about justifying demand, utility, financing, and purpose. The complete procedure, from beginning to end, will be covered in this post. With development in technology, there are multiple ways to construct a building structure. However, in the blog, we will be discussing traditional construction Vs 3D Printing.

Traditional construction methods

Traditional building construction methodology involves development on-site, i.e., starting up with the foundation and then walls and closure with a roof. Let us now understand notable traditional construction methods in detail.

Brick and mortar

This could easily be the most used construction method in the modern era.

- The intricate process of bricklaying starts with site preparation.

- The initials of the process include leveling the ground and making sure the foundation is sturdy. Then it is all about supplying the wall with the proper height and thickness.

- After being soaked in water to stop them from absorbing moisture, the bricks are arranged in the appropriate design.

- To ensure stability and durability, the mortar is combined and put to the foundation as well as in between the bricks.

- Using a level to ensure evenness and straightness, bricks are set one at a time.

- Windows and door openings are covered with lintel to sustain the weight of the structure.

- To prevent water damage to the wall, a row of carefully cut bricks called coping is placed above the last layer of bricks.

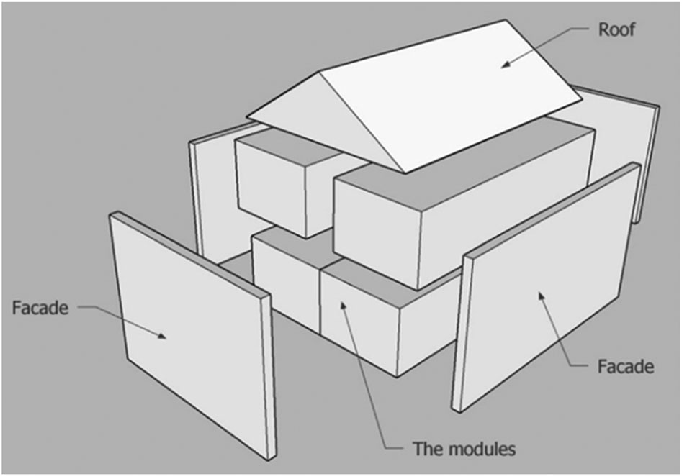

3D Volumetric Construction for Modular Structures

Source:researchgate

Off-site 3D module development is a part of modular building construction, which ensures quality control while saving time and money. Because it is lightweight, strong, and adaptable, light gauge steel is perfect for this technique and may be used in hotels and modular homes.

Construction Using Flat Slabs

By using reinforced concrete slabs held up by columns, flat slab construction does away with beams and offers more design flexibility. It is perfect for prefabricated building since it lowers cladding costs, floor-to-floor height, and construction time.

Twin Wall Technology

Twin wall technology is a contemporary building technique that offers speed and structural integrity by combining precast and in-situ concrete. Lattice girders are used to divide two slabs, and concrete is used to reinforce and fill in any gaps.

Hybrid Construction

Hybrid or semi-volumetric construction combines contemporary building techniques like panel systems and volumetric/modular modules. High-use spaces, such as kitchens and bathrooms, can be constructed as volumetric modules, while the rest of the structure is composed of panels. This enables the best aspects of each construction method to provide benefits, such as the panel system’s flexibility and the volumetric units’ fittings.

Explaining the 3D printing process

Source:wikimedia

The advancement of the 3D printing method itself makes it possible to create a three-dimensional item by superimposing successive layers of material. And with us pursuing it for bigger objects, 3D printing has applications in construction too. The 3D printing construction technique can be used in the creation of individual project components as well as complex structures such as -

- Offices

- Bridges

- Walls

- Modular constructions

- Urban furniture

- Reinforcement molds

- Columns

- Ornamental elements

Let us now understand the process of 3D printing in construction.

The industry’s current proficiency with CAD and BIM modeling makes it simpler to integrate 3D printing technology in the construction business. A CAD or BIM program provides the information a 3D printer needs to create, and the machines begin layering material layers in accordance with the instructions. While several materials may be utilized for this, the most common mix is built of concrete, fiber, sand, and geopolymers.

Modern methods of construction (MMC) are innovative techniques for building structures that are being used more and more in the construction sector. This method can speed up, save money, and make building safer, among other advantages.

Comparing traditional construction and 3D printing

If executed properly, 3D printing could offer unique advantages over traditional construction. Let us now understand sequentially how 3D printing can really change your construction game.

Getting Product Fast

Traditional construction technologies require mold manufacturing and factory ramp-up, taking 15-60 days for the first parts. 3D printing offers a shorter lead time and efficient prototyping process, reducing time to market and ensuring better success prediction.

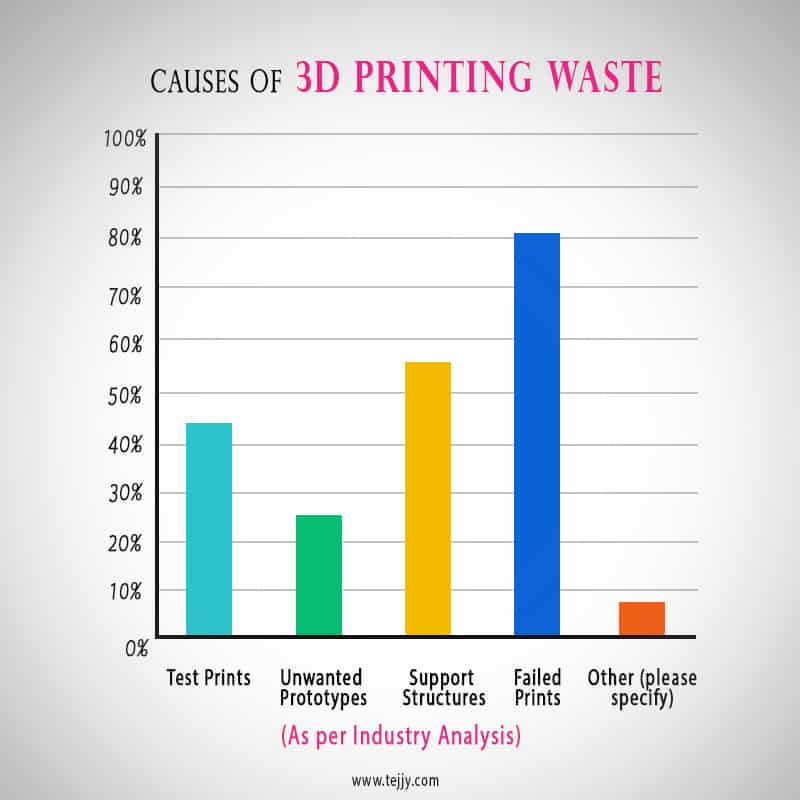

Avoid waste

3D printing is a resource-efficient method used in construction, offering advantages for small, one-off production runs and complex pieces. It reduces lead time and waste and allows for customization. The technology is also popular in robotic arms, construction 3D printers, and concrete. The future of 3D printing is expected to improve with more materials.

Cost Difference

3D printing offers a cost-effective and efficient alternative to traditional construction methods, with buildings produced up to 45% less expensive and requiring fewer materials, reducing assembly time and labor, but also presenting challenges.

Swifter project execution

Houses made using 3D printing may be built up to 20 times quicker than those made with conventional techniques, saving a lot of time and money. By printing ten houses in ten weeks and intending to reduce building costs by 20%, partners 14Trees and Holcim have shown the full potential of 3D construction printing technology.

Reduced requirement of reinforcement

Because 3D printing does not require reinforcing or precast components, it is a more environmentally friendly choice. In addition, it uses less energy and materials to build, making it a more environmentally friendly option than conventional techniques. As a result, 3D-printed homes are more environmentally friendly.

Design freedom

By enabling architects to produce more creative and personalized designs, 3D printing has completely transformed the building sector. This technique does away with the need to pay extra for curved walls or rounded corners. Dar Al Arkan, for instance, has designed a home with clever elements that provide customers with a customized experience. This establishes a new benchmark for the real estate sector and shows promise for a more personalized approach to building design. The promise of 3D printing in the building sector is demonstrated by the fact that 3D-printed homes are more visually beautiful than conventional ones.

Further Reading

What is vertical design construction?

Horizontal vs. Vertical Construction

Horizontal Construction: Types, Benefits & Key Factors

BIM in Oil and Gas Refinery Industry Construction Projects

Construction Risk Management | Types, Process And Benefits